Advanced Production Technologies Tailored to Your Needs

At AFB Group, our production capabilities are designed to offer comprehensive solutions across metal, rubber, and plastic categories. Using cutting-edge technology and rigorous quality control processes, we ensure each product meets our high standards of precision and excellence.

Metal Category

Our metal production services encompass a wide range of techniques to suit various industrial applications:

• Casting & Precision Casting: We provide general and precision casting services, perfect for creating complex shapes and high-detail components with superior strength and finish.

• Hot Forging & Cold Forging: Utilizing both hot and cold forging, we shape metal under extreme pressure to improve its structural integrity and performance characteristics.

• Machining: Our CNC machining services offer unparalleled precision in metal cutting, shaping, and finishing.

• Welded Manufacturing: We specialize in creating strong, durable welds for construction and industrial applications.

• Twisted Manufacturing: Our twisted manufacturing processes produce high-strength, twisted metal products for various uses.

• Laser Cutting: For precise cuts and fine detailing in metal sheets, our laser cutting technology is state-of-the-art.

• Press Brake Production: We use press brakes to bend sheet metal into specific shapes, ensuring accuracy and repeatability.

• Welded Case Production: Our capabilities include the production of robust welded cases for industrial machinery and equipment.

Rubber Production

We manufacture high-quality rubber parts utilizing advanced molding processes. Our products are designed for durability and performance, tailored to meet specific industry standards and client specifications.

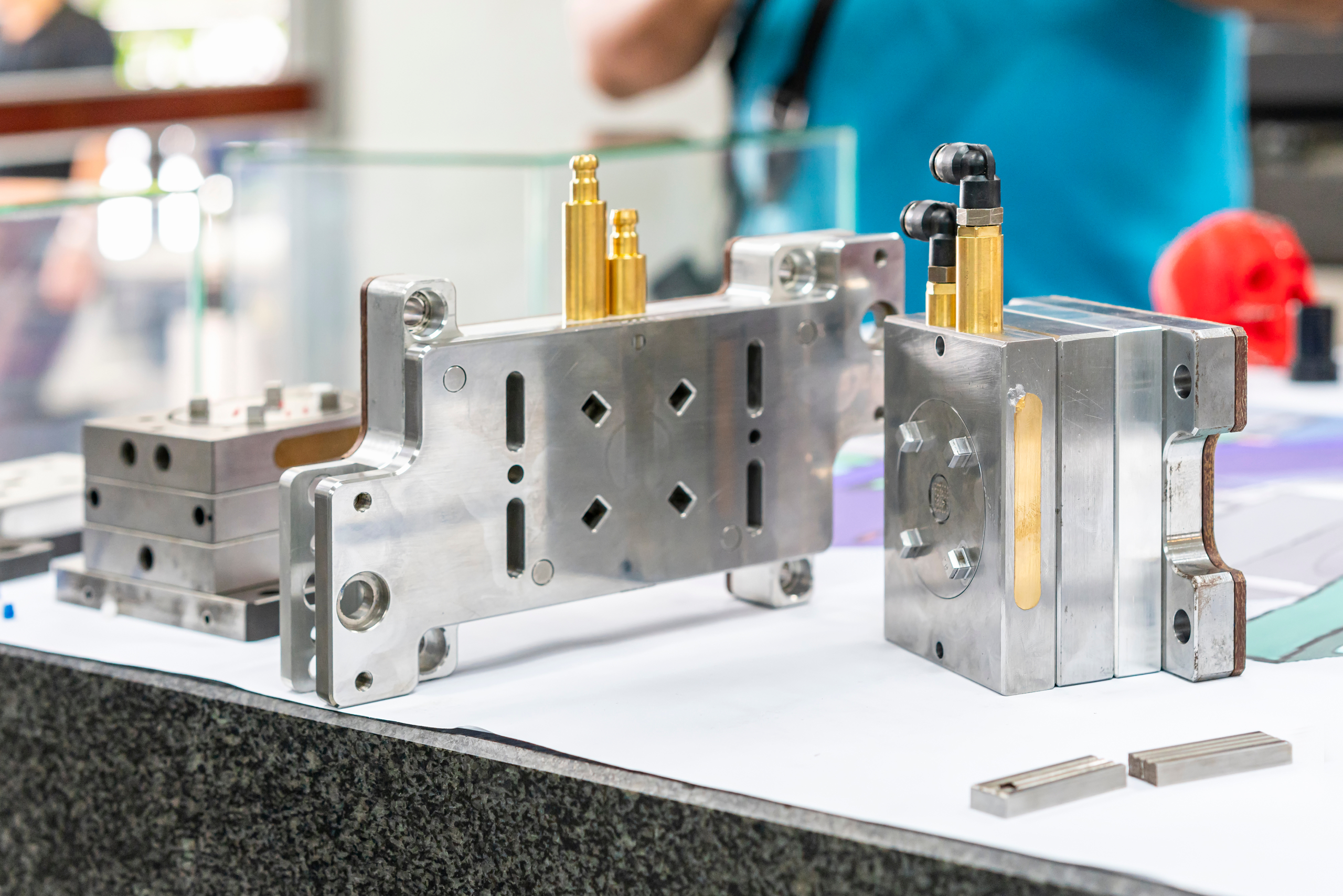

Plastic Injection

Our plastic injection molding process is optimized for high efficiency and quality output. We produce a wide range of plastic parts, from small components to large housings, all customized to client needs.

Explore our diverse manufacturing capabilities and let AFB Group help streamline your production process. Whether you need detailed metal components, durable rubber parts, or high-quality plastic injections, we have the technology and expertise to deliver. Contact us today to discuss your specific manufacturing requirements.

Customized Parts

Bespoke Manufacturing Solutions at AFB Group

At AFB Group, we understand that every industry has unique challenges and requirements. That’s why we specialize in creating customized parts that meet the precise needs of our clients. From initial design to final production, our process is geared towards delivering personalized components that enhance product performance and operational efficiency.

Our Customization Process

- Consultation: We start with a thorough consultation to understand your specific needs, challenges, and objectives.

- Design & Prototyping: Utilizing advanced CAD software and rapid prototyping technologies, we develop and refine your part design until it meets your exact specifications.

- Material Selection: We help you select the perfect materials for your parts, considering factors like strength, flexibility, temperature resistance, and cost.

- Production: With state-of-the-art equipment for forging, casting, machining, and molding, we manufacture your parts to the highest quality standards.

- Quality Assurance: Every custom part undergoes rigorous testing and quality control procedures to ensure it performs as expected in real-world applications.

Examples of Past Projects

Delivering Custom Solutions across Industries

At AFB Group, our diverse capabilities allow us to take on projects that span various industries and requirements. Here are some highlights from our portfolio of past projects, showcasing our ability to deliver tailored solutions that meet specific customer needs.

1. Automotive Sector: High-Performance Engine Components

• Project Details: Custom-designed metal parts for a leading automotive manufacturer to enhance engine efficiency and performance.

• Outcome: Enhanced vehicle performance with increased durability and lower maintenance costs.

2. Construction Equipment: Durable Machine Parts

• Project Details: Production of heavy-duty metal components for construction machinery, designed to withstand extreme conditions and prolonged use.

• Outcome: Our parts contributed to the machinery’s enhanced performance and longevity, resulting in increased productivity for our client.

3. Consumer Electronics: Custom Plastic Casings

• Project Details: We developed lightweight, durable plastic casings for a new line of consumer electronics, focusing on aesthetics and functionality.

• Outcome: The project was a success, providing the client with an aesthetically pleasing and functional design that enhanced the product’s market appeal.

4. Healthcare Industry: Precision Medical Devices

• Project Details: Manufacture of complex components for medical devices, requiring high precision and compliance with strict industry standards.

• Outcome: The components were delivered with the required precision, contributing to the reliable functionality of medical devices.

5. Food Processing: Hygienic and Durable Components

• Project Details: Custom-designed rubber and plastic parts for food processing equipment, ensuring hygiene and resistance to wear and chemicals.

• Outcome: Our solutions helped improve the safety and efficiency of food processing operations, adhering to health and safety regulations.

6. Aerospace Applications: Lightweight Forged Components

• Project Details: Production of lightweight, high-strength forged metal parts for aerospace applications, requiring meticulous precision and testing.

• Outcome: The parts met all aerospace standards and contributed to the overall safety and efficiency of the aircraft.

7. Renewable Energy: Components for Solar Energy Systems

• Project Details: Custom metal frames and supports for solar panels, designed to enhance durability and withstand environmental factors.

• Outcome: The solar panel installations saw improved stability and efficiency, aiding our client’s sustainability goals.

Through these projects, AFB Group has demonstrated its capacity to adapt to client needs, deliver high-quality products, and contribute positively to the advancement of various industries. Each project underscores our commitment to innovation, quality, and customer satisfaction.

Each project is a testament to our commitment to excellence and innovation in manufacturing. Whether you need a single prototype or a full-scale production run, AFB Group is equipped to deliver customized solutions that drive your success.

Explore how our tailored manufacturing services can help you achieve unparalleled results. Contact us today to start your custom project with AFB Group.